Graepel Surfaces

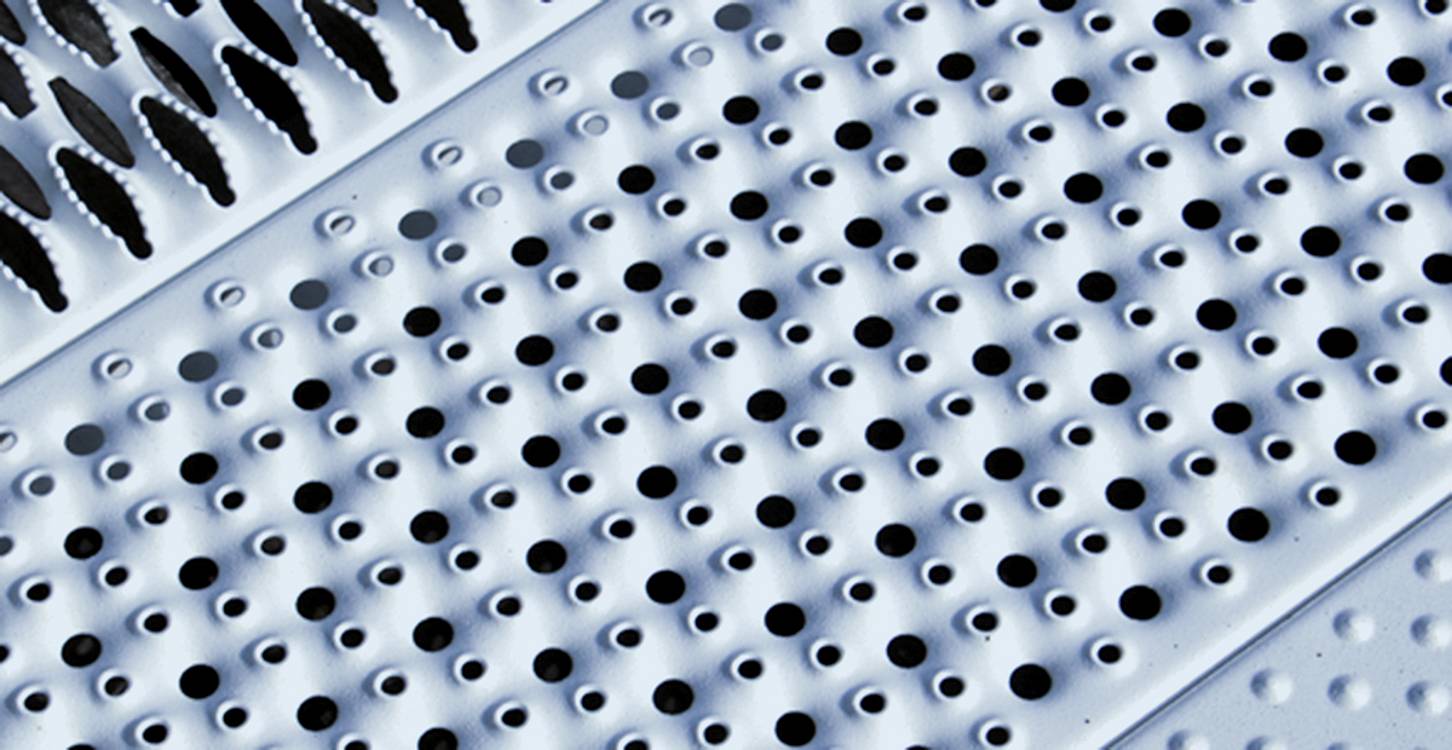

As a full-service partner, we offer our customers a comprehensive range of services, including a wide variety of surface treatment processes.

Of course, you can expect the first-class Graepel quality you are accustomed to when it comes to surface treatment. One more benefit: Your cooperation with us eliminates the need for time-consuming and costly consultation with third parties. Because we handle the development and production of your perforated sheets, gratings and grilles – and we do it just as reliably and competently as we handle the In-house E-coating and powder coating, hot-dip galvanizing and pickling of those components.

![[Translate to EN:] Graepel Produkte - Oberflächenanlage [Translate to EN:] Graepel Produkte - Oberflächenanlage](/fileadmin/_processed_/1/2/csm_graepel-produkte-oberflaechen-anlage1_caab59f56f.jpg)

At our locations in Löningen and Seehausen, Germany, we have specialized in implementing a variety of surface treatments:

in Löningen we make use of the latest generation of cathodic electrodeposition and powder coating plants. Here, we produce coatings in the first-class Graepel quality our customers are accustomed to. Ongoing innovations allow us to develop our products continuously. Graepel Oberflächentechnik is also an established player in the market as a contracting coating company.

Our team in Seehausen operates an in-house hot-dip galvanizing plant as well as an aluminum and stainless steel pickling shop. Corporate and private customers alike can request the team’s services. You only have one item? We can do that, too.

![[Translate to EN:] Graepel Produkte - Oberflächenanlage [Translate to EN:] Graepel Produkte - Oberflächenanlage](/fileadmin/_processed_/7/9/csm_graepel-produkte-oberflaechen-anlage2_018be7fd75.jpg)