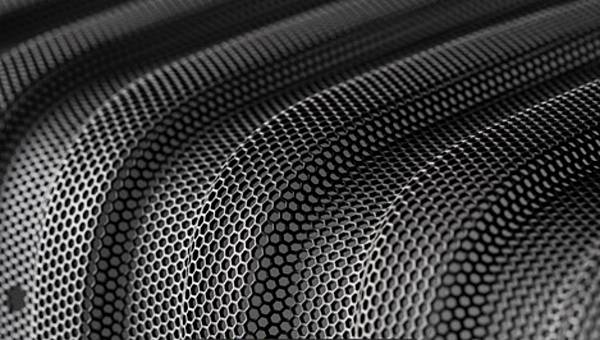

Graepel surface and corrosion protection

As a full-service partner, we offer our customers a comprehensive range of services developed over many years, including a wide variety of surface treatment and finishing processes. We assist you throughout the entire process chain – and confidently ensure the long service life of your sheet metal plates and gratings.

In-house cathodic dip and powder coating, hot-dip galvanizing and pickling shop. Furthermore we have been working diligently for more than ten years to improve the airflow and corrosion protection of your Graepel products as part of our anti-corrosion initiative.

Your advantages with Graepel: high-grade, consistent quality from a single source – without the need for tedious coordination with third-party suppliers.

For more than ten years, the Graepel Group has been working diligently to improve the airflow and corrosion protection of your products. The two pillars of our initiative: Graepel surface technology and our innovation Graepel DuraVent.